Last Updated on July 14, 2022

What is a Beam in Construction?

There are different types of beams which are utilized in the construction of buildings and structures. Vertical loads, shear stresses and bending moments can all be resisted by these mostly horizontal structural elements. Beams carry loads exerted along their length to their ends which include foundations, walls, columns and etc.

Beams were made of wood in the history but they may also be made of steel, concrete or a combination of materials. There are many different cross section forms available such as square, circular, rectangular, I-shaped, T-shaped, H-shaped, tubular, and etc. Straight, curved or tapered beams are all possible to be constructed.

Why do we use many types of beams?

Beams are structural elements that serve the structure by supporting the loads of floors, roofs and ceilings. They do it by transfering the loads to the columns which they are connected to. Heavier and larger beams known as transfer beams are often utilized to transfer the combined weight of the structures.

Understanding the fundamental physics and engineering statics concepts is crucial to dimension and shape the many types of beams used in construction. A structural engineer is educated and qualified to analyze the loads acting on a beam, calculate the forces and stresses it is subjected to, and make the appropriate decisions regarding the beam’s size, material and shape. Many engineering consultancy companies have services to their clients that include the structural design of beams in a new construction as well as the redesigning or rearranging the reinforcement of the existing beams in a structure.

What are Types of Beams Used in Construction?

1. Fixed Beam

Fixed beams are types of beams that are fixed anchored at both ends. Fixed beams are not allowed to be moved vertically or rotated. There will be no bending moment in this beam. Fixed beams are mainly subjected to shear force and are commonly used in trusses and other similar structures.

In other words, a fixed beam is one whose ends are not allowed to rotate. In reality, the ends of a beam are never totally fixed even though they are frequently modeled for simplicity. They can, however, be simply restrained enough according to the stiffness of the beam and column to be regarded as fixed.

2. Cantilever Beam

A cantilever is a rigid structural member that is placed horizontally and is only supported at its one end. It often extends from a flat vertical surface such as a wall, to which it must be securely anchored. A cantilever, like other structural elements, can be constructed as a beam, slab, plate or truss.

When exposed to a structural load at its far free end, the cantilever transfers the force to the support, causing shear stress and bending moment. Cantilever structural members enable for overhanging structures to be built without the need for extra support.

Cantilevers are often used in construction, most notably in cantilever bridges and balconies. Cantilevers in cantilever bridges are often designed in pairs, with each cantilever supporting one end of a center section. A jetty or forebay is a cantilever in a typically timber-framed structure.

3. Continuous Beams

To improve structural stability, beams can be designed continuous over the supports. In the occurrence of a failure of a beam’s span, a continuous beam provides an alternate load way. Continuous beams and frames are preferable in buildings and bridges in seismically prone areas. A continuous beam is a structure that is statically indeterminate.

Continuous beam refers to a statically indeterminate multi span beam supported by hinges. These beams are held up by two or more supports. Continuous beams can have either free or fixed support. It is not required to provide support at the ends of a continuous beam. The continuous beam’s end span can also be a cantilever beam. The continuous beam requires that at least one support produce a reaction along the beam axis. The second moment of area stays constant within each section. However, it is not required that the moment of inertia be the same for all parts of the continuous beam.

4. Reinforced Concrete Beam

Reinforced concrete beams are structural members which are used to support transverse external loads. Across their length, the loads generate bending moments, shear forces and in some cases, torsion. Concrete is very strong in compression but very weak in tension. Steel reinforcement is thus used to withstand tensile stresses in RCC beams. Beams also withstand loads from walls, slabs, other beams and columns. Loads are transferred to columns by reinforced concrete beams in a structure. RCC beams can be produced by shuttering at construction site or come from plants as precast concrete beams.

5. Timber Beam

For hundreds of years, timber has been the primary construction material. It was readily accessible in Europe and was frequently utilized until steel and concrete became the preferred materials at the beginning of the twentieth century. Despite the fact that timber was probably the first material used in the history of bridges, the use of stones and masonry has remained as the main bridge material from the time of the ancient Romans until the use of steel and concrete at the end of the 18th century.

Timber post and beam construction is a construction method that consists of horizontal beams and vertical structural elements that are joined together to form a structural frame into which walls are built. Because this frame is structural and supports the roof load, the number of interior walls may be decreased, allowing for the creation of open plan areas.

6. Steel Beam

A steel beam is a type of structural steel product designed to withstand heavy loads. Steel beams are produced in a variety of sizes and forms, which explains why they are used in a variety of constructions and buildings. The form, size and geometry of beams are determined by a structure’s requirements. Straight or curved beams can be used.

Steel beams are made of molten steel that is poured into molds and rolled out in a variety of forms, similar to beams. Steel beams are durable and have high strength when compared to other types of construction materials. Steel beams are utilized in a variety of construction projects such as buildings, steel roof trusses, hangars, workshops, bridges and etc.

7. T Beam

Because of their monolithic structure, the slab and rib form a T-Beam. The concrete below the neutral axis has no bending moment resistance and only helps to embed the tensile steel. Because the intensity of compressive stress is so low just above the neutral axis, the section of concrete immediately above it bears relatively little compressive force. T-beam is more commonly used than a beam of the rectangular section.

The flange of the beam helps to withstand compression by increasing the area of concrete in the compression zone. As a result, the resisting moment of the beam section increases. If the flange is in a tension zone, the concrete area of the flange is neglected and the beam is considered as a rectangular beam.

8. Composite Beams

Composite beams are types of beams that are made of two or more materials with different modulus of elasticity. Multilayer beams which are formed by joining several sheets together such as sandwich beams that are formed by separating high-strength material faces with a relatively thick layer of low-strength material such as plastic foam, and reinforced concrete beams are some examples of composite beams.

Composite beams are made of more than one material to improve strength or stiffness. I-beams with a plywood web and solid wood flanges are some common examples of composite beams. Pipe beams may also have an exterior liner composed of a different material.

9. Simply Supported Beam

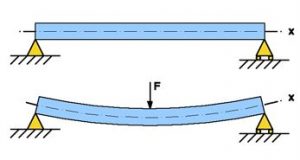

Simply supported beams are types of beams that are supported by two supports and have no restraints against horizontal movement. Beams in structures, bridges and machine tool beds are examples of typical practical uses of simply supported beams with point loadings. Although, for equilibrium, the amount and type of these forces cancel each other, the moments are significant since they generate both stresses as well as beam curvature and deflection. Furthermore, shearing force and bending moment values will often vary along a beam.

In other words, one of the most simple designs is the simply supported beam. It only has two supports, one at each end. The first one is a pinned support and the second one is a roller support. This design prevents the beam from moving vertically at both ends while allowing it to rotate freely. The roller support allows it to expand and contract axially whereas the pin support prevents horizontal movement.

By removing any of the supports and adding an internal hinge, the simply supported beam is transformed into a mechanism that is a body that moves freely in one or more directions. This is obviously undesirable for a load-bearing structure. As a result, the simply supported beam has no support redundancy and if a local failure occurs, the entire structure collapses. These structures with no redundancy are known as critical or determinant structures. A redundant or indeterminate structure, on the other hand, has more supports than are required to restrict its free movements.

10. I Beam

I beam is a structural steel form that is used in structures. It is also known as wide, W, H, rolled joist or universal beam. They are intended to perform an important function as a structure’s support member. These beams are designed to resist a wide range of loads.

It got its name from the similarity of its cross-section to the letter I. These beams are often used to create beams and columns in a range of sizes and specifications. Civil engineers and foremen must understand the significance of I beams in steel constructions.

11. C Beam

When it comes to decreasing production costs or improving profit margins in metal product manufacturing, it may fall to the manufacturer’s engineering team to find ways to minimize product costs without losing quality and structural integrity.

This cost-cutting often begins with your selection of manufacturing and structural profile. While you may be used to creating I beams or T beams, C beams can be an excellent option for many applications. C sections provide high bending in load carrying and soil friction for effective anchoring in ground piling applications. Because the C beam maintains strength tolerances at a smaller gauge than the I-beam, the components are thinner and lighter.

12. L Beam

L beams are end beams that have slabs on just one side. Typically, these beams are cast in a single piece with the slab. As a result, it acts as an L beam rather than a conventional rectangular beam. T beams are formed by intermediate beams. L beams are commonly seen in the corners of buildings where the roof does not project out of the beam, as well as corners around elevator openings, staircases and so on.

In bending, beams resist tension stresses whereas slabs resist compression stresses. Because L beams receive stresses from only one side, they are exposed to significant torsional moments. As a result, L beams experience bending moment, torsional moment and shear force.

13. Lintel

A lintel is a beam that is put over openings in structures such as doors and windows to sustain the weight from the structure above. The width of the lintel beam is the same as the width of the wall, and its ends are built into the wall. Lintels are categorised according to the material used in their construction. Horizontal lintels are less difficult to build than arches.

While timber is still used in the construction of houses, heavier materials such as block, concrete, and stone can also be used, especially in the case of business structures and private condos. As a result, the use of steel lintels has become increasingly popular. Different materials are utilized for lintel construction depending on the cost and availability of resources.

Types of beams with respect to its application

1. Precast beams

Precast beams are types of beams that are cast in plants away from the construction site in a carefully controlled environment with optimal conditions supplied to castings to achieve maximum beam strength. They are cast, set and cured in a very controlled atmosphere before being transported to the construction site where the beams are to be utilized and put as a whole.

The geometry of these structural elements can change widely in size depending on the design spans and loads. These beams are made to be as small as possible overall, ensuring great performance in terms of design spans and fire resistance, allowing the usage of a very spacious structural design.

2. Cast-in-place beams

Cast-in-place(cast-in-situ) beams are cast with slabs in one-piece (monolithic) in construction site. Their formwork and reinforcement are prepared and placed in construction site. They merge well with slabs since their concrete cast and hardening process occur at the same time.

Types of beams have been explained in this article. Hope you enjoyed it!

Pingback: Rebar for Concrete in Civil Engineering | techyildiz

Pingback: What is a Shear Wall in Construction Sector? - techyildiz