Last Updated on August 6, 2022

What is Concrete in Construction?

What is Concrete made of?

To understand the properties of concrete, we should the know the concrete itself well. Construction material known as concrete is made of cement, sand and coarse aggregates that are all combined with water and then the mixture is poured to construction site and allowed to dry (hardening). In order to produce concrete, portland cement is the most popular type of cement. Studying properties of concrete and putting them to use in real-world situations is known as concrete technology.

Concrete is used for the construction of foundations, slabs, beams, columns and other load-bearing elements in a structure. In addition to cement, other binding agents can be employed such as lime for lime concrete and bitumen for asphalt concrete which is utilized in the building of roads and highways.

Concrete is a very valuable and important construction material. After all the components which are cement, aggregates, sand and water have been combined in the proper ratios, the cement and water start reacting with one another to form a solid mass. The concrete becomes more rock-like as a result of the fact that water combined with cement and coarse aggregates harden over time.

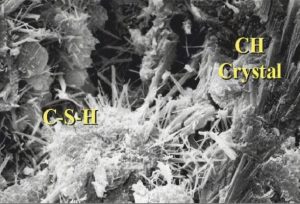

What is CSH Gel in Concrete?

In cement and concrete, calcium-silicate hydrate (C-S-H) serves as the primary binder in components of concrete. It begins to form during the early stages of cement hydration and gradually becomes denser as concrete hardens. After pouring the concrete, the water content in concrete keeps decreasing due to evaporation, which causes lack of hydrogen amount for CSH gels to be formed. For that reason, curing process is crucial for C-S-H gels to be formed properly, which gives concrete’s compressive strength and durability.

What are the Main Properties of Concrete in Construction?

Many factors affect the properties of concrete. The percentage of the cement, water, sand and aggregates is very important for the properties of the mixture. The ratio of these materials primarily controls the various properties of concrete.

1. Durability

Durability is a property of concrete which can be described as the capacity of concrete to withstand abrasion, chemical attacks and weathering while retaining its desirable engineering qualities. Depending on the exposure environment and intended qualities, various concretes require varying degrees of durability.

Most buildings have a design service life of 30 years, although they can serve 50 to 100 years or more. Most concrete and masonry structures are demolished owing to functional obsolescence rather than deterioration owing to their durability. A concrete shell or structure, on the other hand, may be reused if a building’s use or function changes, or if the building’s interior is renovated. Concrete has the capacity to survive nature’s usual degrading processes as well as natural catastrophes as a structural material and as the building’s outer covering.

2. Workability

Concrete workability is a wide and subjective term used to describe how easily freshly mixed concrete can be placed, consolidated, and finished with minimum loss of homogeneity. Workability is a feature that has a direct influence on strength, appearance, quality and even labor costs for placement and finishing operations.

Workability is an important property of concrete that is related to compaction and strength. The ideal workability changes based on the kind of concrete. A thin inaccessible section or heavily reinforced section require more workability than a mass concrete body. As a result, we cannot develop a workability standard for all casting operations.

3. Porosity and Permeability

Porosity and permeability are the properties of concrete that affect the density and strength of the concrete in a considerable manner. Porosity is the ratio of pore volume to the total volume in a material. The rate of moisture flow through concrete under a pressure gradient is referred to as permeability. For moisture to be able to move through voids, voids must be linked to each other and of a specific size. Moisture flow is slowed by discontinuous pores and pores with small openings. Permeability is low in a mature, well-proportioned, well-cured paste even if porosity is in a considerable level. More porous concrete usually has a higher permeability.

The quantity of water, air, and other particles that can enter the concrete mixture is defined as permeability. Concrete has pores that allow these chemicals to enter and leave. Concrete permeability can be a main cause of concrete deterioration because of reinforcing steel corrosion and other degradation mechanisms. Permeability also refers to porous slabs used to drain water from pavements, walkways, and parking spaces, minimizing the need for drainage slopes, structures, and pipes.

4. Mechanical Strength

The strength of concrete determines its quality and it might be the most important property among the other properties of concrete. The strength of concrete is what determines whether it can be used in construction or not. Specific codes are assigned to various buildings to indicate the same concept. In high-rise structures, for example, first-floor columns are more structurally significant than nonbearing walls. A lack of sufficient strength can result in costly, dangerous, and difficult repairs, or, in the worst-case scenario, a catastrophic collapse.

Compressive Strength of Concrete

Compressive strength is a commonly used measure for analyzing the quality of a concrete mixture. This feature of concrete is critical to consider since it is the fundamental indicator of how effectively concrete can resist loads that affect its size. It accurately shows us whether or not a given mixture is sufficient to meet the requirements of a certain project. Compressive strength of concrete typically ranges from 15 MPa to 35 MPa and greater in residential and commercial constructions.

Tensile Strength of Concrete

The tensile strength of concrete is its ability to withstand cracking or breaking under tensile stress. Although concrete is rarely loaded with pure pressure in a construction, calculating the tensile strength is necessary to estimate the degree of the potential damage. When tensile forces exceed tensile strength, breaking and cracking occur. According to studies, the tensile strength of concrete ranges between 2 and 5 MPa. This indicates that the tensile strength is around 10% of the compressive strength on average.

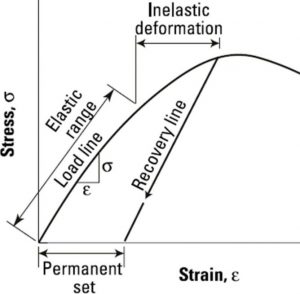

5. Creep

Creep of concrete can be described as the time-dependent structural deformation under sustained loads. Long-term stress on concrete can cause changes in its shape. This deformation generally happens in the direction of the applied force. As an example, a concrete column being increasingly compressed, or a beam bending. Creep does not always result in concrete failure or fracture. When a load is applied to concrete, it suffers an instant elastic deformation and if the load is sustained, elastic deformation becomes creep deformation in time.

The degree of creep experienced by the concrete is determined by the age and strength of the concrete at the time the stress is applied, the magnitude of the sustained loading, and the duration of time that the concrete is under stress. When the concrete is loaded, internal properties such as viscous flow of the cement-water paste, void closure, crystalline flow in aggregates, and water flowing out of the chemical structure of mixture due to drying and loading occur. Aggregates have a significant effect in creep and shrinkage.

Creep and shrinkage are reduced by using a well-graded, coarser aggregate with a low void content. In addition, for low shrinkage and creep rates, hard, dense aggregates that are not absorptive and have a high modulus of elasticity are preferred. Another critical factor in decreasing creep is the type of curing technique used prior to loading. When a high-pressure steamed curing process is used, there is very little creep. Atmospheric and high-pressure steam curing provides very negligible creep in contrast to the seven-day wet curing procedure.

Other factors that influence creep include the kind of cement used, the amount of cement paste used, the size and geometry of the concrete, the quantity of reinforcement bars, humidity, the volume-to-surface ratio, and the temperature.

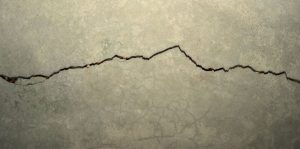

6. Shrinkage

Volume changes in concrete can be either autogenic or induced. One of the most damaging aspects of concrete is volume change, which has an impact on its long-term strength and durability. The feature of volume change in concrete is significant to the practical engineer since it generates invisible cracks in concrete and is referred to as concrete shrinkage.

Concrete shrinkage is defined as the change in length per unit length and is thus a dimensional quantity given as a percentage. Plastic shrinkage, drying shrinkage, and autogenous shrinkage are all time-dependent and are commonly defined in terms of micro strain, which is equal to 1×10-6 m/m.

In other words, concrete shrinkage is described as a decrease in volume over time caused mostly by water movement inside a porous structure of concrete and chemical reactions. The emptying of holes caused by water flow causes tensile forces that pull the cement paste closer together, producing shrinkage, while chemical reactions produce products with a volume smaller than the original components.

7. Fire Resistance

Concrete can not burn – it cannot be ignited, and it emits no toxic smoke when affected by fire. Concrete has been shown to have a high level of fire resistance and may be classified as nearly fireproof in the majority of situations.

This outstanding performance is mostly due to the constituent components of concrete (cement and aggregates), which make a material that is virtually inert and, crucially for fire safety design, has relatively low heat conductivity. Because of its slow rate of heat conductivity, concrete may operate as an efficient fire shield not just between neighboring areas, but also to protect itself from fire damage.

8. Modulus of Elasticity

The ratio of the applied stress to the corresponding strain is defined as the modulus of elasticity of concrete (Ec). It demonstrates not only the ability of concrete to resist deformation due to applied stress, but also its stiffness. In other words, it indicates the capacity of concrete to deflect elastically. The modulus of elasticity of concrete is affected by aggregate and mixture ratios.

The modulus of elasticity, which must be defined in the design of concrete buildings, is very important. In some circumstances, such as the design of pre-stressed concrete structures, linear analysis of components based on elastic theory is used to meet the criterias of ultimate and serviceability limit state.

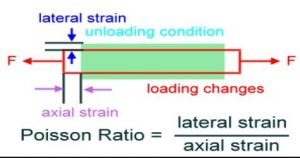

9. Poisson’s Ratio

The ratio of lateral strain to longitudinal strain in a concrete specimen subjected to axial stresses is known as Poisson’s ratio. The longitudinal and vertical strains are caused by the loss in concrete volume under compression force. The volume loss of a concrete specimen is caused by the crushing of tiny aggregate particles as a result of applied stress.

10. Segregation

The separation of cement paste and concrete aggregates during handling and application is referred to as concrete segregation. Over-vibration or compaction of concrete can also cause segregation, with cement paste rising to the top and aggregates sinking to the bottom. Concrete segregation has an impact on the strength and durability of structures and foundations. All concrete aggregates in a good concrete are equally covered with sand and cement paste and create a homogeneous mass.

Due to jerks and vibrations, the cement and sand paste separates from the coarse aggregate during handling, transportation, and placement. If concrete segregates during transportation, it should be thoroughly mixed before placing. However, a concrete that has passed its first setting time should not be used.

11. Bleeding

Bleed in concrete is caused by excess water being pushed to the concrete’s surface. Understanding the causes of bleed can help civil engineers to manage and eliminate its occurrence. Cement, sand, stone and water are the four major components of concrete. Water is the least dense of the four components and the only liquid one. If you drop an object into a pile of stone, sand, or cement, part of the materials will be displaced to the side, but the object will remain on the surface. Dropping the object into water, on the other hand, causes the object to fall into the water and settle on the bottom, causing the water to rise.

In bleed, the aggregate and cement are the objects that sink to the bottom in the same way. Excess water that has not been absorbed by the sand and cement rises to the surface. This creates a pool of water on the concrete’s surface, which is called as bleed water.

12. Fatigue

Fatigue of concrete is the phenomenon of rupture caused by repeated loadings, each of which is less than a single static load that exceeds the material’s strength. Fatigue occurs when a material fails due to direct tension or compression, bending, torsion, or a combination of these effects.

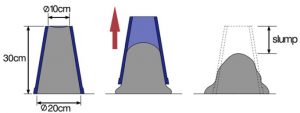

What is Concrete Slump?

The workability or consistency of concrete is measured by its slump. In other words, it measures how easy it is to work with concrete. As a result, the slump of concrete shows what kind of construction the concrete is suitable for. The more slump, the more fluid or workable the concrete is. Low slump indicates that the concrete is less fluid and less workable. If the slump of the concrete is too low, it will be difficult to work with it. If it’s too high, there’s a chance of aggregate segregation and loss of strength.

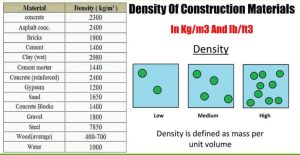

What is the Density of Concrete?

Generally speaking, we can say that the density of concrete is 145 lbs. per cubic foot, or roughly 2,400 kg. per cubic meter. The aggregate content and density, the quantity of air trapped or intentionally entrained, the cement concentration, and the largest aggregate size utilized all affect the concrete’s density. A square foot of lightweight concrete has a density of 115 lbs or 1750 kg per cubic meter.

Since density of a material is equal to mass divided by volume, density of concrete changes according to the grade of concrete. For example, the content and ratio of the components in C30 and C20 concrete are not the same. Therefore, mass of the concrete changes depending on the material proportions. So, the density changes.

We have seen 12 properties of concrete in this article, hope you enjoyed it!

Pingback: Construction Site Management in Civil Eng. | techyildiz