Last Updated on July 16, 2022

What is a Slab in Construction?

Many types of slabs are used in construction; the slab is constructed to provide a flat surface that is generally horizontal within the floor, bridge, roof and other structures. Walls or reinforced concrete beams cast along the slab and structural steel beams and columns from the ground can all be used to support slabs. The slabs are composed of reinforced concrete and carry the weight from the beams to the columns and subsequently to the ground below in both load-bearing and framed structures.

A slab is generally with thicknesses ranging from 100 to 500 mm and is supported by columns, beams and walls. Concrete slabs are a type of slabs that are used to build flat horizontal surfaces like roofs and floors. Compared to its other two dimensions, the thickness of a slab, a flat, two-dimensional planar structural component, is quite thin. It offers a flat area or covering for work in structures. Its main job is to bend in one or more directions and transfer the load. Ceilings, roofs, floors and bridge decks all use reinforced concrete slabs. A structure’s floor system can be in many different types including pre-cast units, ribbed slabs and etc. Slabs can be fixed to walls, monolithic concrete or steel beams, or even straight to the columns. The primary purpose of a concrete slab is its flexural behavior and its design pupose is similar to that of beams.

Different Types of Slabs Used in Construction

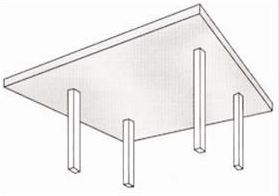

1. Flat Plates

A flat plate is a one-way or two-way system that is often supported directly by columns or load-bearing walls. It is one of the most popular types of slabs used in construction and structures. The flat plate floor has a uniform or nearly uniform thickness with a level soffit that requires just basic formwork and is straightforward to construct.

The floor provides a lot of flexibility when it comes to placing horizontal services above a suspended ceiling or in a bulkhead. The economical span of a flat plate for low to medium loads is typically restricted by the requirement to manage long-term deflection and may need appropriately prestressed. A cost-effective span for a reinforced flat plate is 6 to 8 m while a cost-effective span for prestressed flat plates is 8 to 12 m.

2. Flat Slabs

A flat slab is a system of one-or two-way slabs that do not have girders or beams where load is transferred to the supporting columns and to the load-bearing walls which are also known as drop panels. They increase the shear capacity and rigidity of the floor structure under vertical stresses, resulting in a longer lifespan.

Thin flat slabs ranging from 5 to 9 m in length can be selected for constructing in-situ concrete frame structures. These slabs are commonly utilized on hotels, commercial buildings, parking decks and other locations where beams are not desirable.

Flat slabs are ideal for places where the tops of partitions should be sealed to the slab soffit for fire or aesthetic purposes. Because partition heads do not need to be carved around downstand beams, flat slabs might be said to be faster and more cost-effective than other types of slabs. Flat slabs can be built with a nice surface finish to the soffit, allowing the use of exposed soffits. This enables the use of the building’s thermal mass in the design of cooling and heating requirements, resulting in increased energy efficiency.

3. Waffle Slabs

A waffle slab is a slab with holes underneath that gives the shape of waffles. It is typically used where wide spans are necessary to avoid having many columns blocking space. As a result, large slabs spanning between large beams are necessary. Because the steel bar reinforcement provides the majority of the tensile strength of the slab, only the rib including the reinforcement are kept while the remaining unused concrete part below the neutral axis is removed to lower the slab’s self-weight. Before casting the concrete, clay pots or other forms are placed on the formwork to give the desired shape.

In other words, the waffle slab system is a modern technique of creating concrete slabs that provides great strength and durability while considerably lowering building cost. The waffle slab, which is built on-ground instead of in-ground, removes the need for labor intensive trenching, which is necessary in traditional concrete slab building methods. Construction is carried out on leveled clean surfaces, allowing work to continue uninterrupted in rainy days. Furthermore, waffle slabs enable for more accurate calculation of concrete volumes.

4. Hardy Slab

A hardy slab is a type of concrete slab made of hardy bricks. Hardy bricks are in shape of concrete hollow blocks. These bricks are used to fill up the gaps in the slab. Hardy slabs minimize the quantity of concrete in the slab as well as the slab’s own weight. When compared to conventional slabs, this types of slabs are usually thicker. Hardy slab installation differs from standard slab installation. The use of hardy slab is commonly observed in Dubai and China.

The installation of formwork, the placing of hardy blocks, the placement of reinforcement in gaps between blocks, the placement of steel mesh to the blocks, and lastly the pouring of concrete are all steps in the construction of a hardy slab. It is cost-effective for spans up to 5m in length, decreases the amount of concrete used below the neutral axis, and imposes moderate live loads. It’s built in places where the temperatures are quite high.

5. Hollow Core Slabs

Hollow core slabs are prestressed concrete sections with a uniform cross section. They are created by embedding high tensile strength prestressed strands or single wire into the element. These elements are manufactured using extruder and slipformer machines, which cast in one phase along a production bed without the use of any formwork. Because of their numerous benefits and different applications, hollow core slabs are highly developed structural elements that are used all over the world.

Because of their technological and economic features, they are currently one of the most well-known prefabricated elements. Hollow core slabs are commonly used in residential, industrial, commercial and infrastructural construction for flooring and wall panels. Hollow core slabs can be utilized with a variety of supporting structures, including concrete walls, steel structures, brick walls, prefabricated beams, on-site concrete cast structures and so on.

Hollow core slabs are widely used in infrastructure to protect highways from natural hazards. They are used to build anti-landslide and avalanche protections, as well as road decking, all of which require high loading limits.

Furthermore, hollow core slabs have certifiable fire resistances and are a cost-effective way to build fire stop walls for warehouses, parking lots and industrial buildings.

6. One Way Slab

A one way slab is a flexural member with a low thickness compared to other dimensions that bears gravity loads applied normal to and directly to its surface. It has a span in one direction between parallel supports and it is reinforced for flexure in one direction only.

The primary tension reinforcement bars are placed parallel to the shorter span and are often positioned at the slab’s bottom. A minimal quantity of reinforcement is placed in the transverse direction (longer direction) to prevent temperature and shrinkage effects in that direction. The distribution steel or secondary reinforcement is the name given to this type of steel reinforcement.

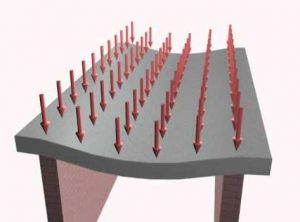

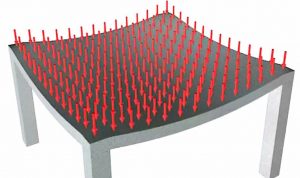

7. Two Way Slab

Slabs that are supported on all four sides are known as two-way slabs. Because the load is distributed in both directions in two-way slabs, major reinforcement is applied in both directions. When the ratio of longer to shorter span length is less than two, the slabs are described as two way slabs. The deformed shape of these slabs resembles a kitchen plate when it is under uniform loading.

When a corner of a simply supported two-way slab is not restrained, it tends to lift the support, resulting in the occurrence of negative moments. As a result, the corner reinforcement should be placed at the two-way slab’s discontinuous edge.

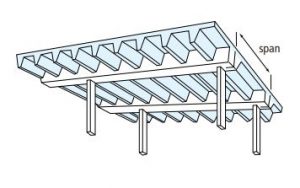

8. Joist Slab (Rib)

A one-way joist floor slab includes a number of narrow reinforced concrete T beams joined by girders which are supported by the building column. T beams are joists that are produced by placing steel in regular intervals. Concrete is placed between such intervals to form those ribs and the slab is likewise produced in this manner. The slab becomes the flange of the T beam.

Adding voids to a slab’s soffit decreases dead weight and improves the efficiency of the concrete part. Although a little more deeper section is required, the stiffer flooring supports larger spans and the supply of holes. It is economical in the 8 to 12 m span range. The material savings are usually offset by some formwork difficulty. With the development of expanded polystyrene moulds, the option of trough profile has become easier and the usage of traditional T moulds has essentially been phased out. Ribs should be at least 125 mm wide to allow reinforcement bar placement.

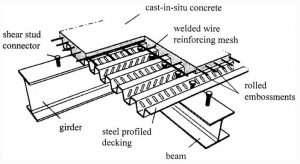

9. Composite Slab

Composite slabs are types of slabs that are made of reinforced concrete that is cast on top of profiled steel decking that serves as formwork during construction and as external reinforcement at the end. The decking can be re-entrant or trapezoidal. Trapezoidal decking can be deeper than 200 mm, in which case it is referred to as deep decking. Additional reinforcing bars may be used in decking troughs, especially for deep decking. When high loads are joined with long periods of fire resistance, they are occasionally necessary in shallow decks.

The steel is galvanized and might be in a variety of thicknesses, with a typical thickness of around 1 mm. Because it is so thin, stiffeners are required to prevent local buckling when used as a bare steel section to carry the wet weight of concrete and other construction stresses. The re-entrant stiffener used at the decking’s top not only stiffens the upper flange but may also be utilized to hold hangers for relatively lightweight objects hanging from the soffit. Interlock is done by including embossments into the decking profile and trapping the concrete around the re-entrant sections of the profile.

10. Bubble Deck Slabs

Bubble deck slab is a unique method of combining air, steel and concrete in a two-way structural slab. Hollow plastic balls are inserted in a steel-reinforced slab. The final structural member reduces up to 35-45% of the concrete that contains carrying effect. It may be applied in most buildings, particularly those with open floors such as commercial, educational and other organizational structures.

The insertion of gaps results in a 35-45 percent lighter slab, which decreases the loads on the walls, columns, foundations and the whole building. Components of bubble deck slab are two-way ribbed plates of reinforced concrete or precast concrete with spherical shaped bubbles. These slab elements are made of a bottom and an upper concrete section that are connected with vertical ribs that are placed around the gaps.

11. Precast Slab

Precast concrete slabs may be useful for any construction project. Usage of these slabs are flexible, which allows them to be placed into structures and foundations in many ways. Concrete slabs are utilized in a wide range of construction works, from simple home projects to big commercial structures. Because it is poured in a controlled environment, precast concrete provides an advantage over conventional slabs.

Precast concrete slabs are considerably durable and have high strength. Because of the way it is manufactured, these types of slabs may actually get stronger and more stable with age. As the concrete sets and hardens, the lack of environmental disturbance throughout the manufacturing process becomes a significant benefit. These slabs are not in the risk of being damaged by minor faults and they may age with no dilapidation.

Precast concrete slabs are resistant to a variety of factors including water damage, fire and decay in the environment. Furthermore, the slabs are generally unaffected by long-term usage or consistent wear. Precast slabs are also designed to be considerably easier to care and maintain than other materials. They are generally non porous materials that require very little upkeep and maintenance to retain their original form and function.

12. Post Tensioned Slabs

Post tensioned slabs are generally flat slabs or ribbed slabs. Because concrete is used up to its strength and is generally held under compression, post tensioned slabs are thin slabs. Thanks to its prestress, post tensioned slabs may allow to design larger spans than other types of slabs.Because post tensioned slabs are thinner, the amount of concrete and reinforcement bars needed are decreased by up to 20% – 30% when compared to conventional concrete slabs.

Except for the tensioning process, the construction of post tensioned slabs on grade is so similar to that of reinforcing steel. Cables are chaired and positioned as the engineer determines to go through the middle of the slab. Tendons measuring 48 inches on center are typical in residential projects. Steel should be used a lot more in commercial foundations. Tendons may simply be routed around obstacles. Post tensioned slabs show less cracking, higher durability, and cheaper maintenance costs. Their deflection can be adjusted by changing the amount of post-tensioning applied to balance any portion of the applied loads just after stressing.

This approach is used by designers to create buildings and structures with clear open areas that allow for more architectural freedom. The total weight of a structure can be reduced by decreasing the thickness of each structural floor and the ceiling to floor height of each level. This can provide less excavation in below-grade buildings and a reduction in overall building height in above-grade structures.

Main Functions of Slabs Used in Construction

- Heat, fire and sound insulator.

- Slabs support dead and live loads by transfering them to beams and columns.

- They provide flat surface to be utilized.

- They provide space between slab and ceiling for building utilities.

- The slab becomes the ceiling for the storey underneath.

Minimum Thickness of Concrete Slabs

The size of slabs and stresses on a concrete slab determine the thickness of the slab. For residential and commercial buildings, a slab thickness of 4-6 inches (100–150 mm) is typically considered, with design-specific reinforcement features. For various types of slabs, several techniques are used to determine slab thickness. For instance, the thickness calculation for a one-way slab is different from a two-way slab and is simpler.

One of the key steps in the design process is choosing and calculating the slab thickness, taking into account the various types of slabs. In addition to achieving a safe and economical slab thickness, using the right approach for slab thickness calculation will significantly shorten the design time.

Main Factors Affecting the Thickness of Slabs

- Fire requirements

- Dead and live loads

- Construction requirements

- Deflection limit requirements

- Vibration limit requirements

- Concrete durability

Types of slabs used in construction have been explained in this article. Hope you enjoyed it!

Pingback: Tensile Strength of Steel, Yield Strength | techyildiz